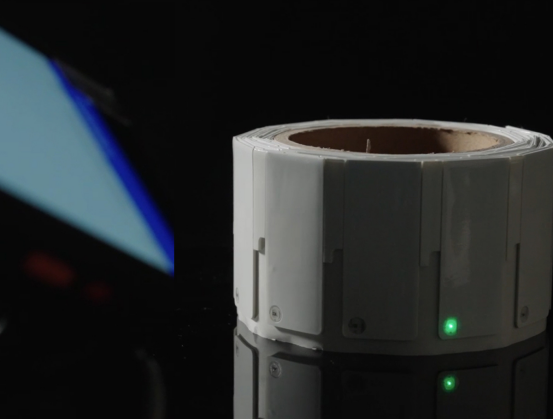

Innovative Flexible Anti-Metal RFID Tag with LED Indicators for Enhanced Asset Visibility

The integration of LED indicators into RFID technology marks a significant leap in industrial asset management. The latest Flexible Anti-Metal RFID Tag combines robust metal-surface compatibility with real-time visual feedback, addressing critical gaps in traditional tracking systems. Designed for harsh environments, this tag delivers dual functionality: reliable RFID communication and intuitive status indication, making it indispensable for industries like aerospace, automotive, and heavy machinery.

Dual-Mode Operation: RFID and Visual Signaling

Unlike conventional anti-metal tags, this model features embedded LED lights that activate in two scenarios:

-

1.Successful RFID Read/Write: A steady green light confirms successful data transmission during inventory checks or maintenance updates.

-

2.Error Alerts: A flashing red light signals issues like tag damage, low battery (for active versions), or failed authentication attempts.

This visual feedback eliminates guesswork in crowded storage yards or dimly lit factories, reducing manual verification time by up to 70%.

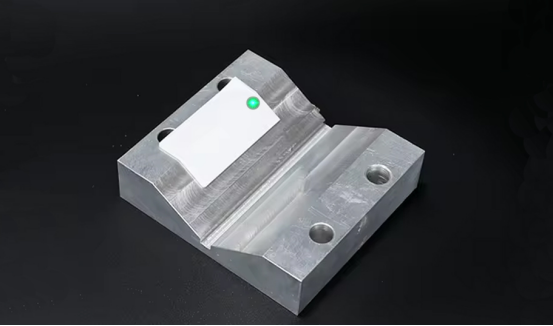

Optimized for Complex Metal Surfaces

Engineered with a flexible PPS (polyphenylene sulfide) substrate, the tag adheres seamlessly to curved or irregular metal surfaces, including engine blocks, tooling equipment, and pipeline valves. Its 0.8mm ultra-thin profile withstands vibrations up to 15G and temperatures ranging from -40°C to +150°C. The anti-metal layer uses a proprietary ceramic-polymer composite to minimize RF interference, maintaining a consistent 8-meter read range even on high-dielectric surfaces like aluminum or stainless steel.

Industrial-Grade Durability

-

IP69K-rated encapsulation resists high-pressure washdowns, chemical spills, and abrasive particles.

-

500,000+ bend cycles ensure longevity on moving parts like robotic arms or conveyor components.

-

Replaceable CR2032 battery (optional active version) supports 5+ years of LED operation.

Smart Manufacturing Applications

-

1.Predictive Maintenance: LED patterns warn technicians about overdue equipment servicing.

-

2.Warehouse Picking: Tags on metal shelving illuminate to guide workers to target items.

-

3.Quality Control: Red LEDs activate if a tagged component fails assembly line inspections.

Customizable Data Fields

The tag’s 512-bit memory supports:

- Equipment ID and maintenance history

- Safety certification expiry dates

- Customizable LED trigger thresholds

By merging optical signaling with RFID precision, this tag creates a bidirectional communication channel between assets and operators. Its flexibility, durability, and intelligent features set a new benchmark for Industry 4.0-ready tracking solutions, particularly in environments where both metal interference and human-machine interaction are critical challenges.